Cordless circular saw purchasing advice: how to choose the right product

- The most important facts in brief

- Battery-powered hand-held circular saws can be used flexibly, as they do not require a mains connection.

- The more powerful the tool, the smoother, faster and cleaner the cut.

- Pay particular attention to safety devices such as a switch-on lock, a riving knife and a pendulum bonnet.

Basic equipment for the home workshop

Power tools are not exactly cheap. That is why many handymen and do-it-yourselfers only acquire a new product when the tool is indispensable. Although there is a dedicated tool for every purpose, some tools overlap in their range of use, so a workshop does not need everything. However, few DIYers can get around a hand-held circular saw. Whenever long straight cuts have to be made, especially through wood, a hand-held circular saw is used. Unlike a normal circular saw, a hand-held circular saw is not stationary. It can therefore be taken in the hand and used freely.

Battery-powered models are particularly flexible to use. Corded circular saws, on the other hand, have to be used near a mains connection. Secondly, the cable is often in the way when sawing. Both of these problems are eliminated with a cordless circular saw. On the other hand, their power is not as high as that of corded models, which is why they cannot cut through every material. In addition, the service life is limited. For long work, you need one or more charged spare batteries for cordless circular saws.

Pro points

- Flexible use

- No disturbing cable available

- Precise and straight cuts possible

Drawbacks

- Not strong enough for every material

- Spare batteries necessary for long use

Important purchase criteria

Although battery-powered circular saws are often somewhat less powerful than mains-powered models, they still achieve a high speed and can cut any type of wood. The performance of the devices is strongly dependent on the battery voltage.

Speed of rotation

Battery-powered circular saws usually achieve between 2,000 and 4,000 revolutions per minute. Particularly powerful models can even reach 5,000 revolutions per minute. The faster the saw blade rotates, the smoother and smoother the saw works. In addition, the higher the speed of rotation, the faster the cutting speed and the cleaner the cutting result.

Rechargeable battery: Power for the long term

The batteries of most cordless circular saws have a voltage of 18 or 20 volts. The weaker 12-volt models are mainly mini circular saws. The battery capacity is usually between 2 and 6 ampere hours (Ah). An average model can be used for about an hour before the battery needs to be recharged or replaced. Circular hand saws are available both with and without a replacement battery.

The charging time of the batteries can be between 45 minutes and 3 hours, depending on the battery and charger. If a quick-charge mode is available, it is even only 20 to 30 minutes. In the long run, however, using the quick-charge mode can shorten the battery’s lifespan.

The usual 18-volt battery weighs between 350 and 450 grams, which is about one tenth of the weight of the cordless circular saw. Depending on the manufacturer, this costs about 20 to 50 euros. 20-volt versions are usually a few grams heavier. However, they are not much more expensive.

18 volts: With voltage into the future

18-volt batteries are the most common type for power tools. Metabo was the first to realise that it is neither sensible nor sustainable for each company to provide a separate battery for each tool. This is how the first battery system was created, namely the Cordless Alliance System (CAS). Bosch copied the concept and founded the Power for all Alliance as well as the Professional 18V System based on the same concept. Some manufacturers, such as Makita, also introduced a battery system, but only for their own – 360, to be precise – tools (as of September 2021).

Such battery systems make the purchase of a cordless hand-held circular saw with an 18-volt battery particularly attractive. The more devices with the same battery voltage and from the same battery system you buy, the more worthwhile it is to buy an 18-volt battery device. You save money and space by using batteries from different manufacturers or different devices. One battery can now be used for several tools. Above all, rechargeable batteries are environmentally friendly. Although rechargeable batteries are better than disposable batteries in this respect, their production is not exactly environmentally friendly. It is more effective to reduce the need for rechargeable batteries and thus their production.

The following table provides an overview of the manufacturers of power tools that have already joined the respective 18-volt battery systems (as of September 2021):

| Cordless System | Manufacturer | Founder |

| Cordless Alliance System | Metabo, Mafell, Rothenberger, Collomix, Eibenstock, Eisenblätter, Haage, Starmix, Steinel, Rokamat, Birchmeier, Edding, Fischer, Prebena, Cembre, Pressfit, Jöst, Trumpf, Gesipa, Montipower, Scangrip, Baier, Ith | Metabo |

| Power for all Alliance | Bosch, Gardena, Gloria, Wagner, Rapid, Steinel, Flymo | Bosch |

| Professional 18V System | Bosch Professional, Brennenstuhl, Cox, Fein, Heraeus, Klauke, Ledlenser, Lena, Ramset, Sonlux, Wagner | Bosch Professional |

The saw blade: diameter, width, cutting depth

Usually, the diameter of saw blades on cordless circular saws is between 160 and 190 millimetres and the radius is therefore between 80 and 95 millimetres. However, the radius of the saw blade and the depth of cut vary. A maximum of one third of the saw blade peeks out at the bottom and is used to cut through. The cutting depth of most models is between 40 and 60 millimetres. This value is specified by the manufacturer and is decisive for the purchase decision. The cutting depth can be adjusted continuously. Make sure that the maximum cutting depth is shorter for mitre cuts.

The cutting width of cordless hand saws is often between 2.0 and 3.2 millimetres. This value is particularly important for precise work. After all, if you make a straight cut with a mark and centre the saw blade, you are effectively sawing 1.0 millimetre off the workpiece with a 2 millimetre cutting width. It is therefore advisable to position the saw blade at the edge of the mark.

Proper handling: Everything under control

Uncomfortable handling is particularly disadvantageous during long periods of manual work. Ideally, handling the tool should also be a bit of fun.

Handle

One of the most important features of a cordless circular saw is its handle. It should fit comfortably in the hand. A rubber coating provides a secure grip and ensures that the tool does not slip, even with sweaty hands. There should also be a small grip on the top of the tool to ensure ambidextrous use. Some manufacturers such as Bosch or Makita also offer their most popular models for left-handers. The motor, handles and saw blade are mounted mirror-inverted on left-handed circular saws. However, such models are considerably more expensive than the standard versions.

Size

The size of cordless circular saws is similar across manufacturers. Many devices are about 35 centimetres long, 20 centimetres wide and 25 centimetres high. The main differences in size are in the saw blades. As far as the housing size is concerned, there are only noticeable differences between normal circular saws and mini circular saws. The latter are small enough to be used one-handed. However, the power and cutting depth of mini versions is also lower.

Weight

The weight varies. Battery-powered circular saws weigh between three and five kilograms. For most people, this is not a lot to lift once. But if you operate the tool for several hours, you will feel the difference in weight.

Angle of inclination

As a rule, the tilt angle of the saw blade on cordless circular saws is adjustable. This function is particularly important for making mitre cuts. The angle can be set between 0 and 45 degrees, sometimes even up to 50 degrees. Ideally, the tool is equipped with a scale so that the angle can be adjusted continuously and accurately to the degree.

Plus points for gimmicks

Some gimmicks make handling easier. These are LED lighting and the CutControl. The LED lighting comes on automatically when the motor is activated and illuminates the workpiece where the saw blade touches down. This allows you to use the hand-held circular saw even in a somewhat darker workshop. The CutControl is a small hinged plastic part in front of the saw blade. When you fold this down, it helps you to stay on the pre-drawn straight line.

Useful accessories

Cordless handheld circular saws usually come in a case. Buyers can decide whether they want to buy only the hand-held circular saw including the battery or also other accessories. The more extensive the accessories, the higher the price.

A spare battery with a battery charger is indispensable for circular hand saws. With only one battery, you may have to stop working and wait until it is fully charged. A second battery allows you to work longer. If, while you are using one battery, you charge the other, you can work with the batteries alternately for several hours.

A rip fence is also particularly important. This can be attached to the housing of the cordless circular saw and ensures straight sawing. The small device is placed at right angles to the edge of the workpiece and ensures that you saw parallel to it. If there is no parallel edge near the cut, then you can also attach the rip fence to a guide rail, but this is not included with a cordless hand-held circular saw.

Last but not least, an extraction system ensures that hardly any sawdust is thrown around. On the one hand, this makes sense because no chips get into the eyes, mouth or nose. On the other hand, an extraction system considerably reduces the cleaning effort after sawing. However, it must be attached to a hoover hose, which may make handling a little more difficult.

The main thing is safety

Power tools are not exactly safe. The same applies to cordless circular saws. Careful handling is essential when working with them. That is why the tools have several safety devices. However, some safety aspects, such as protective clothing, are the responsibility of the user.

Safety devices

Probably the most important safety device for circular saws is the riving knife, as it prevents dangerous kickback. The riving knife is positioned behind the saw and keeps the kerf open so that the clamped wood does not jam the saw.

A saw blade guard prevents you from touching the saw blade from above, on the one hand, and chips from being flung towards your face, on the other.

The pendulum bonnet covers the lower part of the saw blade to minimise the risk of injury. Only the area used for sawing is excluded.

The engine brake stops the engine as quickly as possible – usually within ten seconds.

A switch-on lock ensures that the saw can only be operated once it has been unlocked, similar to modern weapons.

A construction clamp secures two workpieces stacked on top of each other so that you can safely operate the hand-held circular saw with both hands. However, you have to buy these separately. It is not included in the cordless circular saw case.

Safety instructions

Make sure the workpiece is securely fastened. Then always use both hands to guide the circular saw. Although gloves are often insisted upon in crafts, in the case of a hand-held circular saw they endanger rather than protect the user: If the glove gets caught in the saw blade, the hand is pulled in with it.

It often happens that you have to tinker with the cordless circular saw, for example to replace the saw blade. Before you do this, you should always remove the battery so that the tool does not start unexpectedly. It is also best to wear protective clothing when using the tool. To avoid inhaling chips or getting dust in your eyes, it is advisable to put on protective goggles and a mask. Work trousers that do not tear easily are also an advantage. Last but not least, you should wear safety shoes so that you do not injure yourself if a sawn-off workpiece falls on the tips of your feet.

Saw blade: Important but replaceable

The saw blade of a cordless circular saw is a metal disc with many sharp teeth on its edge. When the motor is running, the disc rotates extremely fast – usually over 3,000 revolutions per minute. The tool is held against the edge of a workpiece and slowly fed through the material. Saw blades differ in the number of teeth and the material, among other things. Not every saw blade is suitable for every application. That is why it is advisable to have several saw blades and to replace them as needed, which can be done in a few easy steps with high-quality tools. It should be noted, however, that not every saw blade fits every cordless circular saw. You need to find out about this in advance.

On the saw blades you can read information regarding the dimensions and teeth. For example, the blade may say: 165 x 30 x 2.4 mm /42 max. 9,500 min. The first number refers to the saw blade diameter. In this case it is 165 millimetres. The second number indicates the diameter of the hole in the centre of the saw blade. This information is important to know whether the saw blade can be fitted to your hand-held circular saw. The third number gives information about the cutting width. This is followed by a number that is often listed together with a “Z”. The “Z” stands for “teeth” – in English often “T” for “Teeth” – i.e. the number of teeth. So here it is 42 teeth. Last but not least, “max. 9,500 min” means that the saw blade may be operated at a maximum of 9,500 revolutions per minute.

The material of the saw blade

Saw blades are usually made of chrome vanadium steel. Saw teeth made of this material are very sharp, but wear out quickly. For this reason, the teeth of high-quality saw blades are coated with hard metal, which increases their cutting durability.

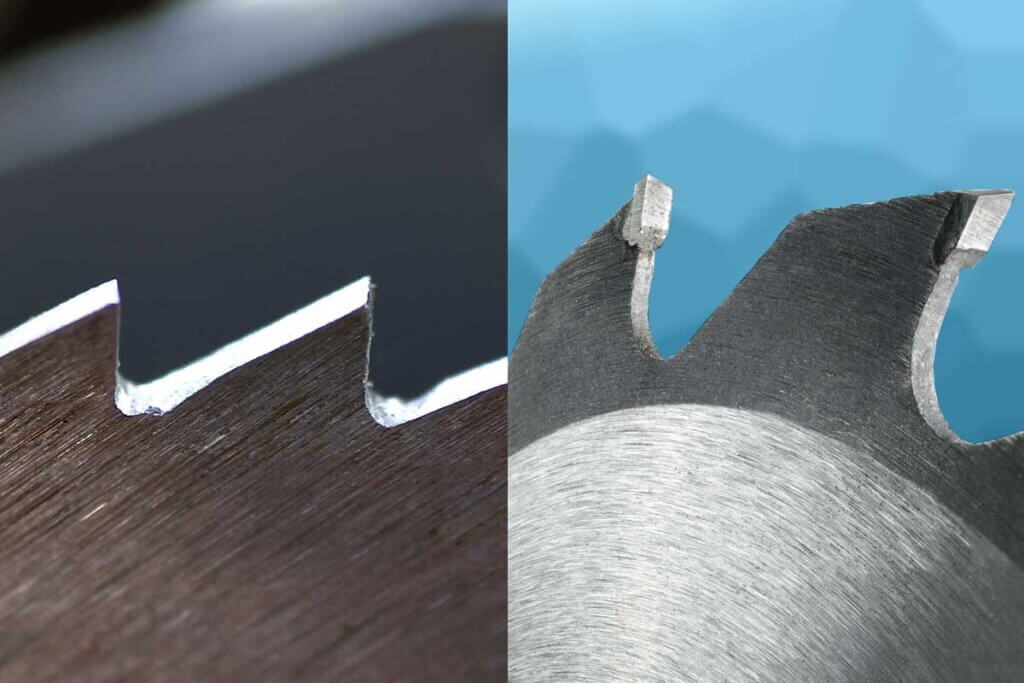

Teeth: Small, but important

The teeth have the greatest influence on the sawing properties of a circular saw blade. After all, they make contact with the workpiece. They determine not only the quality of the cut and the cutting speed, but also which material and which cutting direction – along the grain or across it – a saw blade is suitable for.

Number of teeth

The number of teeth should be considered relative to the diameter. A saw blade with a large diameter needs more teeth. Therefore, it is not the absolute number of teeth that is important, but their size and the distance between them. More teeth usually result in a cleaner cut. However, more teeth are not always better:

If the number of teeth is small, the distance between the respective teeth is large. Such saw blades do not clog as easily during use and cut quickly. They are best suited for longitudinal cuts, i.e. lengthwise to the wood fibres. However, the quality of the cut can be somewhat rough.

If you have a high number of teeth, you can also expect a high quality of cut. Such saw blades should only be used for cross cuts. For longitudinal cuts there is a risk of clogging. However, the cutting speed is lower.

Tooth shape

The tooth shape mainly influences the cutting quality and the tool life. The flat tooth has a flat, rectangular surface. The cut quality produced with it is somewhat coarse and the run is not as buttery smooth as with other tooth shapes. Flat teeth are mainly used for longitudinal cuts for solid wood.

The trapezoidal tooth has a trapezoidal edge and is considered to be of particularly high quality and long-lasting. Such teeth are very robust and are used for hard materials. They also withstand foreign bodies such as nails.

Roof teeth have an angular edge like a roof. They are most often used to saw plastic-coated wooden boards.

Alternate teeth have a slanted edge. They are called this because not every tooth is the same. The edges are arranged alternately on the right and left. Only every second tooth is thus identical. The advantage of this tooth shape is that individual teeth are not subjected to so much stress, which prolongs their life and leads to smooth running. The cut is fast both transversely and longitudinally.

Some teeth are hollowed out. These hollow teeth are particularly useful for veneered workpieces as they produce little tear-out.

Tooth position

The angle of the teeth to the saw blade also plays a role. In technical jargon, teeth that are aligned at an angle are called positive, while upright teeth are called negative. The more inclined or positive the position, the faster the blade cuts.

4,236 reviews

4,236 reviews