Power drill purchasing advice: how to choose the right product

- The most important facts in brief

- A drill is powered either by an electric motor or a compressed air gear.

- For solid material such as stone, a hammer drill is best.

- Precise holes can be made very well with a hammer drill, which is suitable for almost all materials.

- When buying a drill, pay particular attention to the power, the power supply and the drill diameter.

- If you only use the drill for short jobs, you can use a rechargeable model.

The tool for every household

A drill is one of the tools that are particularly useful and therefore should not be missing in any household. No matter whether furniture is to be assembled or only holes need to be drilled, a drill makes the work immensely easier. In the meantime, there are a variety of versions on the market that are suitable for different environments and applications. This makes a drill equally suitable for hobby craftsmen and professionals. The various attachments and model designs make it possible to tackle a wide range of tasks. Drilling machines are usually easy to handle and therefore recommended for every household.

How does a drill work?

A drilling machine consists of a housing with a mains cable for the power connection. Inside the machine, an electric motor or compressed air drive drives a gear train. This translates the high speed of the motor into a lower speed. The gear transmission is also called a gear shift, because often a gear shift enables several speeds, i.e. “gears”. There is a trigger on the handle that is used to start the machine. The harder the user pulls the trigger, the higher the speed of the gear.

Some machines have a speed control below the trigger that allows different speeds. It is usually adjustable whether the rotation is clockwise or anticlockwise. The drill chuck, into which the drilling tool is clamped, is attached to the front part. Depending on the material, a different tool and a different speed are required.

A practical invention

In 1895, the German Wilhelm Emil Fein invented the first electric hand drill, which was then manufactured in his Stuttgart company. The mechanics Friedrich Heep and Jacob Wahl were responsible for the machine’s electric motor. The power of the first electric drill was only 50 watts at 1,200 revolutions per minute.

The different versions of a drilling machine

The choice of drilling machine depends on the material to be worked on. While some variants, such as the impact drill or the hammer drill, are suitable for hard material, other models can only be used for softer material such as wood.

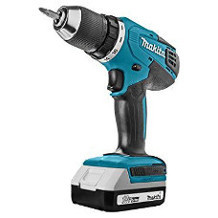

The percussion drill

The impact drill, also known as the hammer drill, is one of the most commonly used drilling machines. It can screw, drill and hammer, which is why it can be used universally. The special feature of this drill is that it has a percussion function, which strikes the drill bit against the material and thus exerts a stronger pressure when drilling. A ratchet toothing on the drill spindle inside the device triggers this impact. This makes the impact drill particularly suitable for working on harder materials for which a normal drill is too weak.

Thanks to the percussion function, the device can deliver several thousand blows in one minute. It has a power of approximately 1,000 watts. A hammer drill is also ideal for drilling precise holes. To use the machine for lighter materials, simply switch off the impact function. However, a percussion drill consumes a lot of power and effort to operate.

The hammer drill

A hammer drill is particularly suitable for drilling in stone and concrete and for chiselling work. It has a smaller number of blows than a percussion drill, but its percussion mechanism works with compressed air and thus enables more impact force. Users therefore need less force to hold on than with an impact drill. However, a hammer drill does not work as precisely as a percussion drill. In combination with a chisel, a hammer drill is ideal for shaping stones or removing tiles.

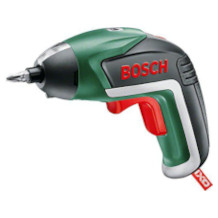

The drill screwdriver

In contrast to the variants mentioned above, a drill screwdriver has no impact function, so it only drills and screws. By rotating the drill chuck, the device can drill holes and fasten screws. The higher the torque of the screwdriver, the better its performance. This machine is particularly suitable for light materials and small holes. A drill screwdriver has very little weight and can therefore be held in the hand for a long time without exerting force. It is inexpensive, lasts a long time and allows you to adjust the torque, which makes it possible to tighten screws more precisely.

The bench drill

A bench drill is a stationary device that enables particularly precise drilling in wood, metal and plastic. The drill chuck is lowered onto the material with the help of a wheel or a crank, so the user does not have to hold the tool in his hand. The material to be worked on is clamped in the corresponding device beforehand. Bench drills are heavy devices that are set up and used in one place. They are therefore much less flexible than other drilling machines.

Other types

In addition to the variants already mentioned, there are many other types of drilling machines. A pillar or stand drill is similar to a bench drill. The difference lies in the size, as a pillar drill, unlike a table drill, is too big for a table and therefore stands on the floor. A sub-type of the pillar drill is the magnetic drill. It works with a magnet that presses the holder onto the workpiece.

A core drill is also suitable for drilling in stone, concrete and masonry. It has no percussion mechanism, but has a higher power than a conventional drill. The drill bit of the machine is either diamond, carbide or high-performance steel. A special form of the core drill is the wet drill. It is used when water cooling is needed during the drilling process. Water flows permanently through a hose onto the drilling surface, cooling both the machine and the materials.

If you want to work particularly filigree and do not need a lot of drilling power, you can use a mini drill. It is small, handy and particularly suitable for hobbyists or model builders. However, this drill cannot work on hard materials such as stone or concrete.

As a special form of a drill screwdriver or impact drill, an angle drill has a head that can be adjusted by 90 degrees. It can be used for particularly hard-to-reach places, for example in masonry.

In contrast to an electric drill, an air drill works with compressed air. However, it must always be connected to a compressor and is therefore less flexible than an electric drill. In private use, the device is therefore rarely used. An air screwdriver is an impact wrench that can loosen stuck screws. It also works with compressed air and is mostly used in car workshops. It precisely unscrews or tightens screws and nuts with jerky movements.

What to look for when buying a drill

If you want to buy a drill, you first have to choose a type of drill. After this initial purchase decision, there are other criteria such as power, power supply, drill diameter and drill chuck system that will help you find the right tool.

Power

When choosing a drill, power is a particularly important purchase criterion. This depends on the size of the drill as well as the material to be drilled. With larger devices, the machine’s motor is more powerful than with smaller ones. If you decide on a drill or a small impact drill, the machine should have an output of between 500 and 1,000 watts. Only then will it have enough power to work on materials such as plastic or wood. However, if you want to use it to work on harder materials, such as metal, the power of the drill must be at least 2,000 watts.

Power supply

Most drills are now available in two versions: corded and cordless. Buyers must therefore make a decision as to which type of power supply they prefer. Corded devices are very powerful and are well suited for longer or more difficult jobs. Although they can be used for a long time at a stretch thanks to the cable connection, they always require a power socket nearby, which means they are tied to a specific location. Due to their heavy weight, they are not as handy as battery-powered models and are therefore not suitable for small jobs such as assembling furniture. If you decide to buy such a tool, you should pay attention to the length and routing of the cable.

Variants with a rechargeable battery can be used for screwdriving, as they are less powerful. However, the battery of the device must be recharged after some time or replaced by another one. Consequently, the usage time is shorter than with a corded tool. Although cordless drills are unsuitable for materials such as concrete or stone, they can easily handle shorter jobs on materials such as wood or plastic. They are usually easier to handle than corded versions and can be used more flexibly.

If you don’t want to buy either a corded or a cordless drill, you can use a pneumatic drill. These do not have an electric motor, but are powered by compressed air. Compressed-air-driven machines are usually very compact, light and easy to handle. However, they are not very flexible because they have to be connected to a compressor.

How large should the drill diameter be?

For the drill to drill a hole with the right diameter, the drill diameter must be correct. This indicates the maximum size of the hole drilled with it. If you want to drill a very fine hole, a drill diameter of two millimetres is good. Some machines even have a drilling diameter of up to 20 millimetres for particularly large holes. For private use, a model with a maximum drill diameter of 13 millimetres is usually sufficient. Since 13 millimetres is the industry standard, most drills have this diameter. However, different drill diameter values are given depending on the material.

Drill chuck system

The drill chuck is one of the most important parts of a drill. The buyer can choose between two different drill chuck systems. The gear rim chuck has a very high tightening force, so that the clamped tool does not slip. However, a special spanner is needed to change it. With a quick-action drill chuck, on the other hand, tools can be changed quickly and without additional tools. The single-sleeve quick-action chuck system, also called SDS drill chuck, allows the tool to be tightened with one hand; with a double-sleeve system, both hands are required. However, the tool can slip during heavy use. On a machine with a gear rim drill chuck, any drill bit can be clamped. Special SDS drill bits are required for a version with an SDS drill chuck.

Weight

The weight of a drill is often underestimated. Drills that weigh more than two kilograms require a lot of power for prolonged use. Impact drills and hammer drills in particular weigh a lot. So before you buy, find out how much the tool you want weighs and whether you can use it without exerting too much force.

How much does a drill cost?

How much a drill costs depends on its type, power and functions. Classic drills with a rechargeable battery are cheaper than electric versions; they are available for as little as 25 euros. However, they are not particularly durable and are usually less precise than higher-priced variants. High-quality brand products, however, can cost more than 100 euros. Impact drills cost at least 50 euros, hammer drills over 100 euros. Cordless screwdrivers can be found at prices between 80 and 300 euros, depending on whether it is a brand product. If you only use your drill once or twice a year, you will be fine with an inexpensive model. For regular use, it may be better to buy a higher-quality product.

Extras for particularly good handling

To ensure that you achieve the best results with your drill, there are a few additional functions and features that make it easier for you to use.

Constant electronics

The constant electronics are responsible for keeping the speed of the drill constant, regardless of the resistance of the workpiece. This simplifies the handling of the machine enormously, but is not absolutely necessary. This function is only available on models with a power of more than 1,000 watts.

Depth stop

A practical aid is the depth stop, which is a longer metal rod. It is attached to the drill parallel to the drill bit and can be adjusted to different lengths. When drilling the first hole, it must be fixed in place so that it rests against the outside of the wall. After that, it ensures that each hole is the same depth. The depth stop is included with almost all impact drills.

Additional handle

If you want better handling of your drill, you can attach an additional handle to the machine. This allows you to exert more pressure on the machine if necessary. Such a handle can be installed individually and is included with almost all drills.

Gear shift

Some high-quality drills have a gear shift that allows the user to choose from two gears. Inexpensive drills, on the other hand, can only reduce the speed. In first gear, the drill works with a lot of power at low speed. This is ideal for holes with a larger diameter. The second gear allows a higher speed with less power behind it. Second gear is ideal for smaller holes, which can be drilled more quickly.

Speed preselection

To set the speed at which the machine should drill, almost all drills have a speed or rpm preselector.

Direction of rotation switch

The direction of rotation of the machine can be set on almost all drills. There is usually a switch near the trigger. This function is particularly useful for screwing screws in or out, as two different directions of rotation are required.

Drill bits

Depending on the material you want to work on with your drill, you will need different drill attachments. For wood, there is a so-called wood drill bit. It has a centre point and two sharp cutting edges, making it suitable for all types of wood. For drilling metal, a metal drill bit is best. It has a conical tip and two sharp cutting edges. A masonry drill is ideal for particularly hard materials such as stone, concrete or tiles. Its wedge-shaped tip made of hard metal penetrates any surface.

Case

To store the drill safely and transport it easily, a drill case is recommended. It also has space for a mains cable, various drill attachments and various accessories. The case is usually made of aluminium or plastic. A protective case is particularly useful if you mainly use your drill outside the home. It is included with many models.

What protective clothing must be worn when drilling?

Since handling a drill is not without danger, it is worthwhile to buy protective clothing. Sturdy gloves will protect your hands from damage by the machine if it slips off. Since splinters and dust are also thrown through the air when working with such a machine, protective goggles are useful to protect your eyes. Because of the loudness, hearing protection is also important.

Tips for using a drill

Working with a drill is basically easy, but requires a little practice. With a few tricks, it is safe to use.

So that nothing gets caught

Before working with a drill, you should take off any jewellery you are wearing. It is best to roll up long sleeves so that the fabric cannot get tangled in the machine. If you have long hair, tie it up before using the drill so that it does not get in the way.

Safe handling

It is best to check the power supply before using the drill. If it is broken or not connected properly, it can pose no small safety risk. Therefore, be sure to check that the cable is whole. If there is even the slightest damage, the cable should be replaced. The cable of the drill should be positioned so that no one can trip over it. Make sure that you stand with both feet securely and firmly on the ground when using the drill. Always hold the drill with both hands when using it so that it does not slip away from you. Check that the tool is properly secured in the drill chuck before you start working. Do not put the drill down until it has come to a complete stop.

Checking is important

Check whether there is a gas, water or electric pipe where you are going to drill. If this is the case, the drilling process can be dangerous. If this is the case, find another place to drill. If you are unsure about the size of the drill or the drilling tool, use a small version first.

2,712 reviews

2,712 reviews