Grain mill purchasing advice: how to choose the right product

- The most important facts in brief

- Grain mills allow you to process different types of grain into flour yourself.

- They are driven either manually by a crank or by an electric motor.

- Special attention should be paid to the material of the grinding mechanism: Stainless steel, natural stone and ceramic-corundum are all suitable.

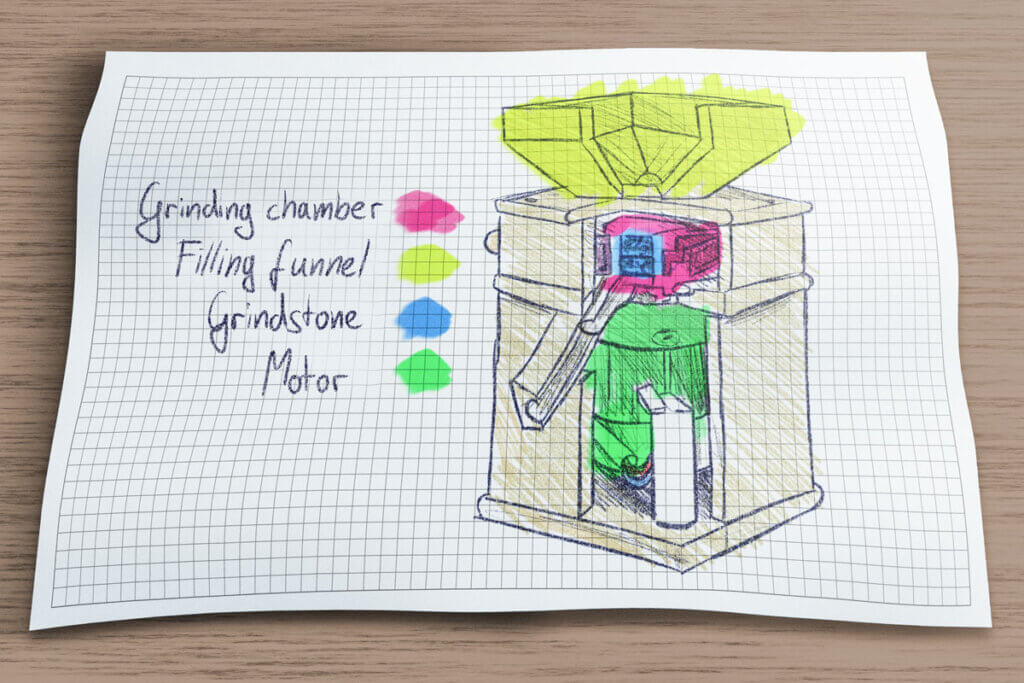

- The hopper filling of grain mills

Fresher than from the baker

“DIY” (Do It Yourself) is currently very popular. Increasingly, consumers are attaching importance to being involved as early as possible in the process of producing and processing food. Bread baking is particularly popular. And if you bake your own bread, sooner or later you will also want to produce your own flour. Home-ground flour is free of undesirable additives. When it is fresh, it not only contains more vitamins and minerals than flour from the shop that has been stored for a long time, it also tastes better.

Once upon a time, processing grain into flour for personal use was a laborious achievement. Today, anyone can grind their own grain: a grain mill allows you to grind any grain such as wheat, rye, oats or rice into fine flour or coarse meal. The ground grain can be used to make various dishes, such as bread, pastries, muesli, tender oat flakes or semolina. You can also influence exactly how much grain you grind, which types of grain you mix, if any, and how coarsely you grind them. Depending on the model, you can even process spices, pulses or oil seeds.

Don’t be afraid of carbohydrates!

Many diet-conscious people avoid carbohydrates these days. This includes cereals, as they consist mainly of carbohydrates. However, unless you have intolerances or allergies to certain grains or ingredients such as gluten, there is no reason to avoid grains. After all, it is a healthy source of energy with lots of fibre and micronutrients.

The type of mill matters

Before you buy a grain mill, you need to know which type of mill is right for you. Do you want to process smaller quantities manually or produce a lot of flour at the push of a button? In addition to grain mills, so-called grain crushers are also available, which do not grind the grain but flatten it into flakes. Some devices are even capable of doing both.

Manually operated grain mill

The timeless design of manual grain mills appeals to many consumers. The devices are powered by a hand crank and are light and compact. As they do not rely on mains electricity, they are very environmentally friendly and can be used anywhere. Due to their purely mechanical mode of operation, they are also less likely to break down. Small hand grain mills are already available from around 30 euros.

However, the output of these mills is limited. You can process between 20 and 50 grams of grain per minute. For a whole family or simply a larger quantity of flour, you will need quite a long time at this rate. Besides time, cranking also costs you strength. The hopper volume of hand-driven models is usually small. Users who want to grind large quantities are better off using electric versions. You can rarely process particularly hard cereals such as maize manually.

Advantages

- Timeless design

- Easy

- Compact

- Environmentally friendly

- Not dependent on electricity

- No running costs

- Durable

- Inexpensive

Disadvantages

- Not suitable for large quantities

- Time and energy consuming

- Usually small hopper

- Not suitable for very hard grain such as maize

Electric grain mill

Electric devices grind more, faster and easier. You can operate them at the touch of a button and the motor does the rest. Depending on the model, 100 to 200 grams of grain are processed per minute. The motor power of electric grain mills for private use is usually between 250 and 600 watts. Even more powerful devices are used in the catering industry. Versions with a motor output of at least 360 watts are best suited for processing hard cereals.

However, the high power and fast processing of large quantities also comes at a higher price. At least 300 euros are required for an electric grain mill. The size of these mills and their motor also mean more weight and more noise – most electric models produce between 40 and 85 decibels. Last but not least, the devices are dependent on mains power. They are therefore less flexible than hand-driven models and come with operating costs.

Advantages

- High performance

- Fast processing

- No force required

- Also suitable for harder grains

- Large hopper capacity

Disadvantages

- Expensive

- Operating costs

- Reliant on mains power

- Difficult

- Loud

Grain crusher

Grain crusher, flake crusher, flaker, whatever you call the device, it is not a grain mill. Nevertheless, it is used to process grain. Strictly speaking, the grain is conveyed through two rollers that flatten or crush it. This is how oat flakes are produced, for example. Oilseeds such as sesame seeds can also be processed with such a device.

Advantages

- Production of fresh cereal flakes, for example oat flakes

- Also suitable for processing oilseeds

Disadvantages

- No grinding function

Combi mill

Combi mills are grain mills and crushers in one. They therefore have a grinding mechanism and a roller that can be used separately, sometimes even in parallel. Since more components have to be accommodated, combi mills are often somewhat larger and heavier than simple grain mills. However, if you use both functions, you save space and money by buying a combination mill, as otherwise you would have to make two separate purchases. If you only use one of the two functions, however, it is not worth buying. Combination mills are cheaper than two separate devices, but more expensive than a simple mill or crusher.

Advantages

- More space-saving than two units

- Cheaper than buying separately

- Grinding and crushing possible

Disadvantages

- More expensive than simple grain mills

- Larger

Grain mill as an attachment for the food processor

If you already own a food processor, you can also buy a grain mill as an attachment. Such an attachment is particularly inexpensive and compact. It needs neither a crank nor a motor. The motor power is provided by the food processor. Its performance is therefore comparable with electric models. Such an attachment is available for as little as 20 euros. However, make sure that the attachment is compatible with your machine.

Advantages

- Small

- Space-saving

- Inexpensive

- High performance

Disadvantages

- Compatibility with food processor not always given

- Cannot be used without a food processor

Natural stone, steel, corundum

The grinding mechanism is one of the most important components of a grain mill. It influences the fineness of the result, the longevity of the device and the selection of foods that can be ground with it. Grinding mechanisms are usually made of stainless steel, natural stone or corundum ceramic.

Natural stone

Natural stone – usually granite – lasts a very long time. In addition, grinders made of natural stone achieve a very fine grind. On the other hand, it is the most expensive material. You should not grind particularly moist, greasy or hard foods with it. However, the grinding result of such grinders can hardly be topped for common types of grain.

Advantages

- Very durable

- Very fine grind

Disadvantages

- Not suitable for moist and fatty foods

- Not ideal for very hard grains like maize

Corundum ceramic

Grinding stones made of corundum ceramic are most commonly used for grain mills. Corundum has similar grinding properties to natural stone, but costs a lot less. It therefore lasts a long time and grinds very finely. Most types of grain can be processed with it. As with natural stone, you should avoid oilseeds and moist grains.

Advantages

- Durable

- Fine grind

- Cheaper than natural stone

Disadvantages

- Not suitable for moist grain and oilseeds

Stainless steel

Stainless steel is a particularly practical material for grinders. It does not stick together or smear easily, for example due to grease or damp grain, and is also easy to clean. Stainless steel grinders are used to grind not only grain but also spices or oilseeds. However, the grinder wears out over time. Stainless steel grinders can usually be replaced in a few easy steps. The biggest drawback of stainless steel is that only a coarse to medium grind is possible. If you want particularly fine flour, for example for bread or even pastries, you should look for a grain mill with a grinder made of natural stone or corundum.

Advantages

- No sticking or smearing due to fat

- Also suitable for spices and oil seeds

- Easy to clean or replace

Disadvantages

- Not very durable

- Not a very fine result

Other purchase criteria

One of the most important purchasing criteria for grain mills is the grinding fineness and, in particular, its adjustability. The hopper capacity determines how much grain you can grind in one piece. The size and weight of grain mills also influence not only transport and storage, but also handling.

Grinding degree

Depending on which grain is being ground for which purpose, different degrees of grinding must be achievable. Not every grain mill is able to guarantee every fineness level from coarse to fine. The decisive factor for the degree of grinding is the mill’s grinding mechanism. With a stainless steel grinder, only a coarse to medium grind is possible. If you want fine flour, for example for baking, you need a grain mill with a stone grinder, be it natural stone or corundum. Ideally, the devices are infinitely adjustable so that you can choose the right grind depending on the intended use. The grinding degree is usually adjusted by a rotary control directly in front of the grinding mechanism, which tightens or loosens the latter.

There is no standard for the fineness of grind of flour – DIN standard 10355, which defines types of flour for ground products, refers to the mineral content not the degree of grinding. However, manufacturers often refer to DIN standard 10765 for coffee in product descriptions. According to this standard, coffee is finely ground if 100 percent of it is smaller than 0.315 millimetres. In the case of cereals such as wholemeal flour, about 8 to 18 percent of the grain cannot be ground so finely, depending on the mill, because it contains fibrous husks. Therefore, if about 82 to 92 percent of the flour is 0.315 millimetres or finer, you can use it to prepare fine baked goods.

Grinding and motor power

Grinding power is relevant for both hand- and motor-driven models. It provides information about how many grams of grain can be ground per minute. The coarser the grind, the faster it can be ground and vice versa. Hand grain mills grind much slower than electric models. You can grind about 20 to 50 grams per minute with them. The grinding capacity is sufficient for a single person. However, if you are grinding for several people or simply a larger portion, you should look for an electric model. Such devices grind between 100 and 220 grams per minute. You may find more powerful models in the catering trade.

Near-diamond grinders?

With nine Mohs, corundum is almost as hard as diamond, which has a hardness of ten Mohs. Besides its use as a gemstone, corundum appears in everyday life mainly as an abrasive, for example on sandpaper or polishes.

With electric grain mills, the motor power in watts also plays a role. This influences the grinding performance of the device. It is also relevant for the energy consumption. In this respect, the relationship between wattage and grinding speed should be taken into account. However, the motor power is most relevant for the hardness of the grindable grains. Not every mill can grind hard cereals or pulses such as maize or chickpeas. Although the material of the grinder also plays an important role, it is important to pay attention to the wattage. For example, if you want to grind maize, you should look for a device with a motor output of at least 360 watts.

Hopper capacity

The size of the household and the intended use have a considerable influence on the required hopper capacity. This is usually specified by manufacturers in grams. Wheat is used as a reference grain. Ideally, you know what quantities you will be grinding before you buy and can get the right device. Some small models can be filled with as little as 50 grams. The largest mills for private use can hold about one kilogram of wheat in the hopper. Only professional devices for gastronomy use have larger filling quantities. At the lower end of the filling quantity spectrum, both manually operated and electric models can be found. For large filling quantities, it is mainly electric models. After all, grinding so much grain in one piece with the crank is very time-consuming and exhausting.

Size and weight

In many kitchens there is a lack of space. Before buying, make sure you have enough space for a grain mill. If you have a food processor, you can save space with a grain mill attachment. The size of a grain mill depends largely on the hopper capacity. Grain mills are usually not very wide. They vary greatly in height. Grain mills for private use are usually between 20 and 50 centimetres high.

Small hand-powered grain mills usually weigh between one and three kilograms. With increasing size and a motor, the weight also increases: heavy electric grain mills can weigh up to ten kilograms. However, grain mill attachments are the lightest, as they require neither a motor nor a crank. They often weigh less than one kilogram. If the mill has a fixed place, the weight does not play a major role. However, if you use it often and put it away again, a heavy appliance can be a nuisance.

Assembly and safety

For good handling and safe use, pay attention to the mounting and installation options of the appliances. Electronic devices usually have suction cups to prevent them from slipping. Hand-operated models, however, are cranked manually and must remain as stable as possible. Similar to the carnivorous cousins of grain mills, meat grinders, the devices must be mounted on the table or kitchen ledge with a screw clamp. The unit should not move when cranking. Special grain mills for on the go do not require a fastening. Many grain mills are also TÜV or GS certified for safety.

Collecting container

Many grain mills come with a collecting container in the form of a bowl. If this is not the case, you will need to use one from your household that is the right size. Some smaller grain mills have a drawer or grinding chamber into which the ground material falls. Smooth materials such as plastic, glass or stainless steel are best for the collection container. Flour chambers are often made of wood. However, flour sticks to wood, which can lead to residue.

Notes on cleaning

The amount of cleaning required for a grain mill depends largely on how much it is used. If only dry cereals are ground in it, some dust and husk residue will remain in the grinder after each use. You can vacuum these up with a small hand-held hoover or remove them with a brush.

You should not use water, as it can dull the grinder. If oilseeds or moist grains have been ground, the inside of the mill will be moist or greasy. In such a case, use rice by tipping it into the funnel to soak up the liquid. If the inside is dry, you can proceed as described above. Grain mills made of plastic or metal are easier to clean than those made of wood, as the materials are smoother.

61 reviews

61 reviews